The Spheronization Process

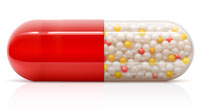

Spheronization is a rapid and flexible manufacturing process that creates small spheres or spheroids for pharmaceutical products. Spheronized products are dense with a uniform size and shape with a defined surface.

- Powder mix of ingredients/ Formula creation

- Formula converted into a plastic mass

- Extruded and processed through a spheronizer

- Spheres are then dried and coated

- Produces a perfectly round, hard, and smooth sphere

FEATURES:

- Approximately 0.6 to 3 mm in diameter

- High level of active ingredients in each sphere

- Rapid and flexible manufacturing process

- Dense with uniform shape

- Customizable ingredients, colors, and formulas

- Specific time release properties

- Enteric coating

- Mixing of incompatible ingredients

- Dust elimination

- Spheres can be combined into a capsule or tablet

- High volume capacity

- Product differentiation

BENEFITS OF ENTERIC COATING:

- Blocks oxidation

- Blocks moisture

- Eliminates taste

- Eliminates odor

- Protects the sphere from ambient heat

- Keeps the product intact during transport, storage, and display

- Controls the release of the formula:

- Immediate

- Delayed

- Sustained

- Compounded

Use your own ingredients or choose from our list of AVAILABLE PRODUCTS:

- Alpha Lipoic Acid

- Caffeine

- Calcium

- Capsaicin

- Capsicum

- Folic Acid

- L-Theanine

- Lutein

- Melatonin

- N-Acetylcysteine

- Niacinamide

- Riboflavin

- Selenium

- Thiamine

- Vitamin A

- Vitamin B6

- Vitamin B12

- Vitamin C

- Vitamin D3

- Vitamin E

- Zinc